(Be careful with FB cables!)

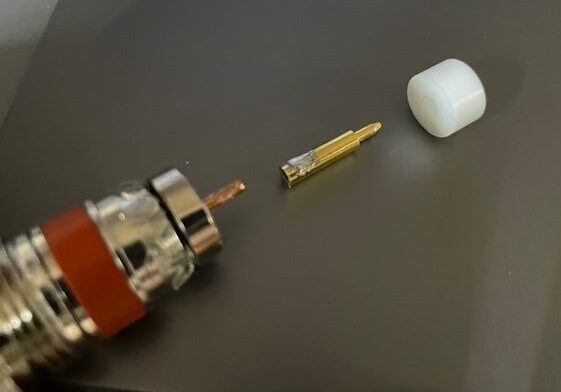

The contact (needle contact point) came out cleanly… What’s more, there was no solder on the core wire of the coaxial cable…

The side hole of the contact where the solder flows in was (seemed to be) completely filled, so it was the perfect example of a weak solder joint.

So what caused this?

I always use a 20W soldering iron to prevent the insulation from melting on the core wire. (On the other hand, I always solder the braided wire of the M-type connector all at once with 60W.)

I think I probably underestimated the fact that the insulation of the FB cable is polystyrene, which is weaker against heat than the 5D2V, and that the N-type contact is small, so I thought it would be easy to solder with a 20W iron. However, the core diameter of the FB cable is 1.8mm, while that of a normal 5D2V is 1.4mm, so the cross-sectional area is 1.7 times larger. That’s how difficult it is to heat up, but… I overlooked that.

I will have to check the other N-type connectors as well, but for now I applied flux to the core wire just to be safe, applied some extra solder, and then re-welded it.

It is an FB cable that has little loss and can be easily replaced with a normal cable, but there are unexpected pitfalls if you do not treat it with the proper care.

→Back to Index